Hollow Metal Doors

Door menu

- 1100 Hollow Metal Polystyrene Core/Fire Rated

- 1200 Steel Stiffened Doors

- 1300 Temperature Rise Doors

- 1400 Doors for Tornado Solutions

- 1500 Lead lined Doors

- 1600 Dutch Doors

- 1701 Hollow Metal Door with Polystyrene Core Bullet Resistant Opening Solution Level 1

- 1801 Steel Stiffened Door Bullet Resistant Opening Solution Level 1

- 1703 Hollow Metal Door with Polystyrene Core Bullet Resistant Opening Solution Level 3

- 1803 Steel Stiffened Door Bullet Resistant Opening Solution Level 3

Standard Door Details

Face sheets to be formed from 12, 14, 16 or 18 Gauge Galvannealed A40 steel. A60 available.

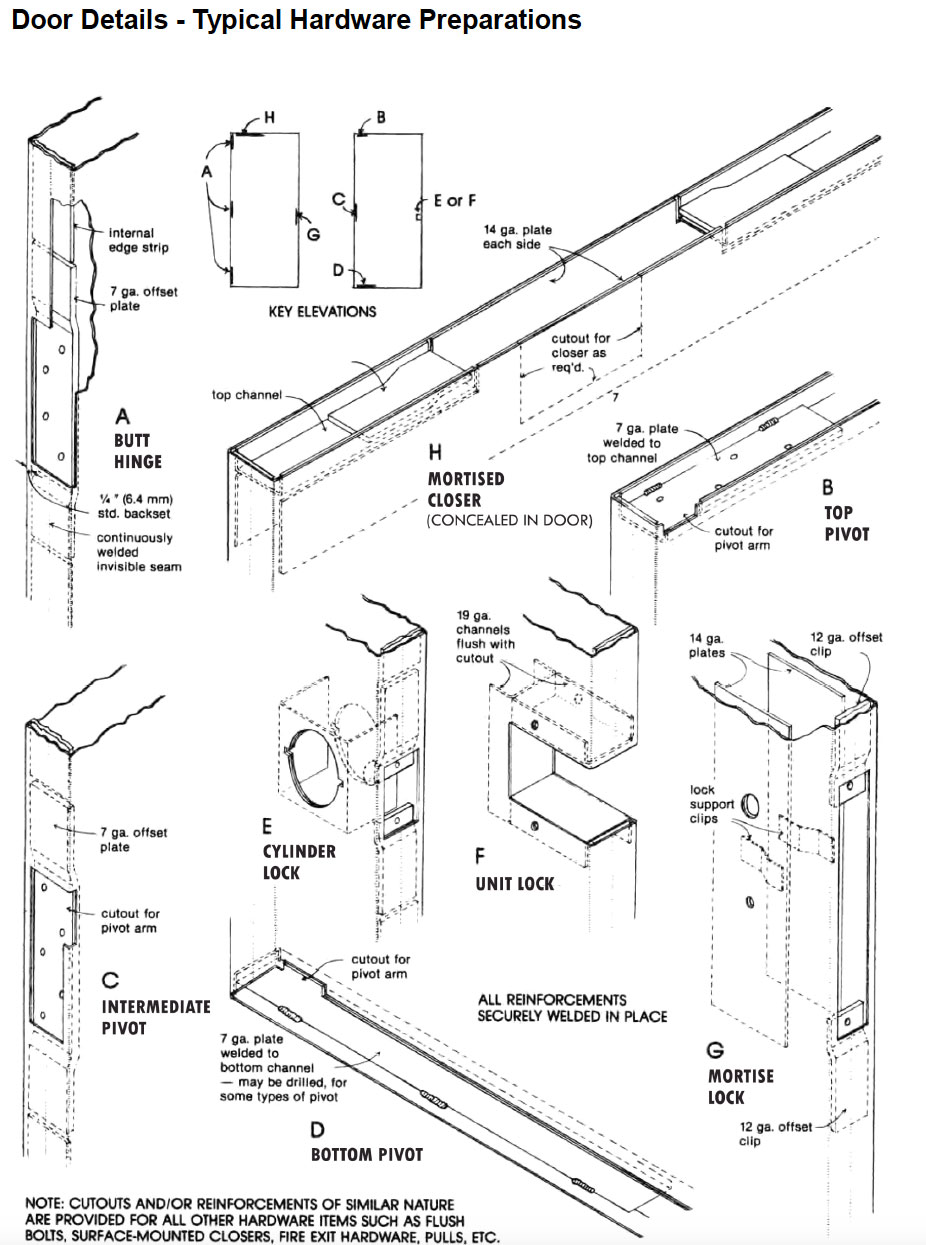

7 Gauge—1 1/4” x 10” joggled hinge reinforcing. Drilled and tapped per template.

12 Gauge mortised hardware mounting tabs.

14 Gauge surface hardware and trim reinforcement, prepared for mortised units by hardware templates.

16, 18, 20 or 22 gauge door ribs, per arch, specifications, vertically spaced at 6” on center—spot welded at 4” on center (standard is 22 gauge) reinforce perimeter of all cutouts with channel.

16 Gauge door top and bottom channels welded in place.

Vertical door edges are to be welded full length and finished smooth and seamless.

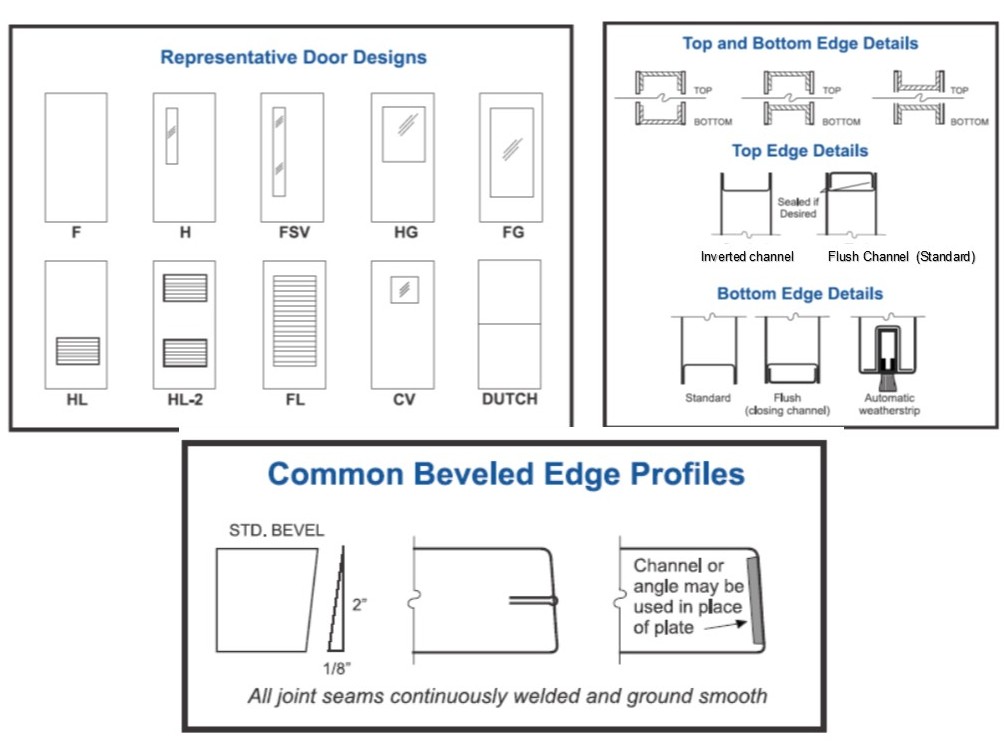

All door glazing stops to be set for 1/4” glass (3/8” space) unless otherwise requested by contractor. (NOTE) Glass should be cut 1/4” less than door cutout (exposed glass opening is 1 5/16” less than cutout dimensions,) Louver size is actual size of door cutout.

Astrangals will be furnished on all exterior pairs of doors where assigned hardware permits. U.L. Rated pairs of doors must have astrangals if removable mullions or 2 vertical rod exit devices are not assigned.

1/8” between pairs of doors, head 1/8”, jamb 1/8” bottom undercut 3/4” unless otherwise noted.

Manufacturing Tolerances

Manufacturing tolerances shall be maintained within the following limits for Doors

- Width +/- 1/32 in. (.08mm)

- Height +/- 3/64 in. (1.2mm)

- Thickness +/- 1/16 in. (1.6mm)

- Hardware cutout dimensions/Template dimensions +0.015”, -0”

- Hardware location +/- 1/32 in. (.08mm)

All Rocky Mountain Metals, Inc. standard and custom hollow metal frames and doors are manufactured in their New Mexico manufacturing plant from materials produced substantially in the United States and as such, meet the requirements of 41 U.S.C 10, commonly known as the Buy-American Act.

All Rocky Mountain Metals, Inc. standard and custom hollow metal frames and doors are manufactured in their New Mexico manufacturing plant from materials produced substantially in the United States and as such, meet the requirements of 41 U.S.C 10, commonly known as the Buy-American Act.